|

|

|

|

|

|

|

|

|

|

|

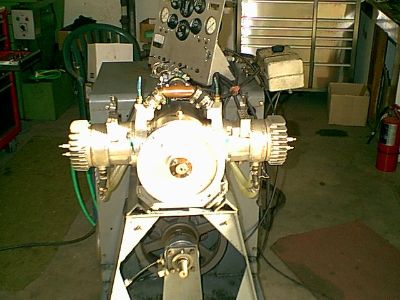

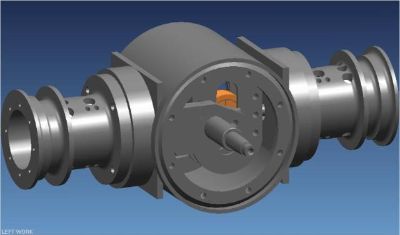

This is my 30" Bourke-Cycle Prototype engine. It was fabricated

around the parameters of the original prints. Video is posted on

bourkeengine.net click the picture

I was surprised the first time it ran, after warm-up, in full diesel,

ignition switched off, with no power loss. The "exhaust note" is

unique. Combustion chamber pulses are supersonic with flame

speeds in excess of 5,000 ft./sec. The secret is in his "combustion

event management". Faster burns allow more time for expansion

and cooling in the cylinder.

Homebuilt Bourke 30 C.I.D. engine.

Initial modeling of the Proto 30" homebuilt engine. Count on

knowing a good tig welder. Bourke's cylinders and cases were

cast one piece. Proto cylinders are built-up from

base turning, weld on intake, transfer, and water jackets.

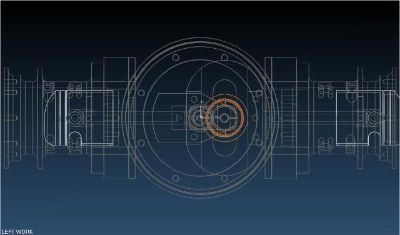

Line drawing cross section. This is a precision assembly. All

parts must be square and true. Parts require no more

precision than current conventionals. Proper heat treatment

and finish grinding go without saying.

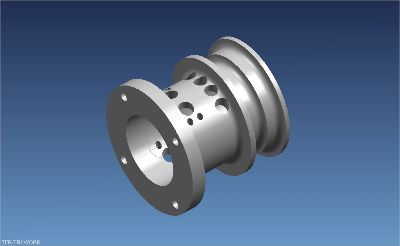

Basic cylinder turning. Gasflow is probably less than optimal

in this type of cylinder, although it satisfied the design intent

of the project. Proto II wil be flow tested.

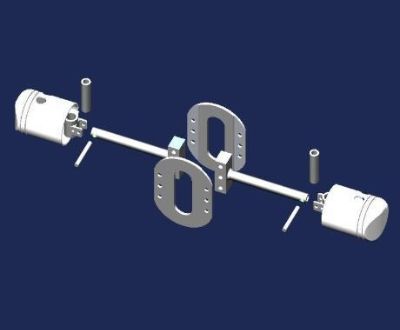

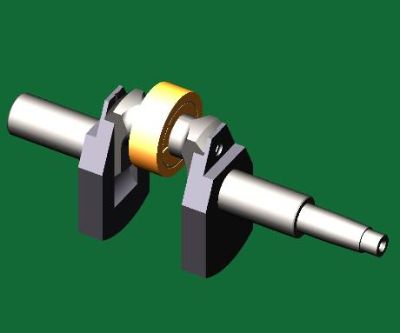

30" crosshead assembly with one piston blanked for clarity.

The geometry generated by this SCOTTISH YOKE is the

foundation of the design. Not only does it generate high

compression, but a LONGER DURATION of the compression

event. What does the formula say about FIXED VOLUME?

Blow-up of the 30" rod yoke assembly. This represents one mass-

the "bullet"- that is thrown between two alternating

explosions (detonations). 100% dynamic balance is produced

by "exchange of momentum" rather than by counterweights.

The faster it revs, the smoother it gets.

Roller cam is counterweighted and spins as smoothly as a

flywheel. Strobe balanced to 10k plus.

My Bourke workbench.

My proto 30" model was made on simple machine tools.

Piston blanks are cast aluminum. With die-casting, cost

per piece can be comparable with conventionals.

Setting-up to bore pin holes and cut transfer slot.

I used my surface grinder with vertical rotary table to grind

cam relief for piston clearance. Cobbled, but it works.